Drive couplings provide the means by which power is transmitted from the electric motor or engine to the hydraulic pump. By virtue of their flexible structure, they are able to compensate angular and radial misalignments between motor and pump, and appreciably attenuate the noise generated through the drive line. The couplings are available in aluminium and cast iron versions, with a variety of spider options, and will cover a range of applications using electric motors from size 63 up to size 400.

In particular:

- cast iron half-coupling SGEG available with screw mounted

- steel half-couplings SGES and SGDR available with screw

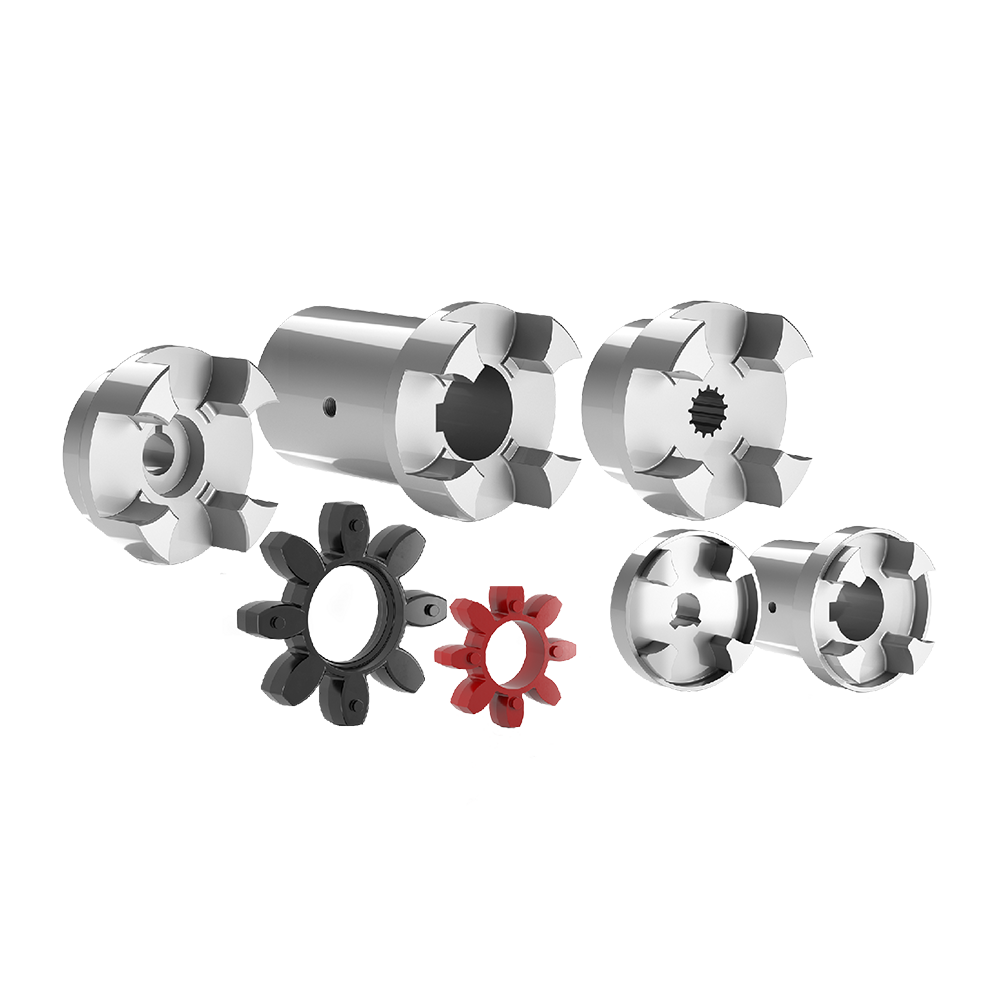

SGEA - SGEG - SGES - EGE

SGEA - SGEG - SGES - EGEFlexible half couplings

Available in aluminium, cast iron, steel and low-noise versions

SGEK

SGEKFlexible half couplings

Aluminum, steel and cast iron construction

Suitable for tortional shaft applications, pump/motor combinations, and internal combustion engines up to 10 HP (7.5 Kw).

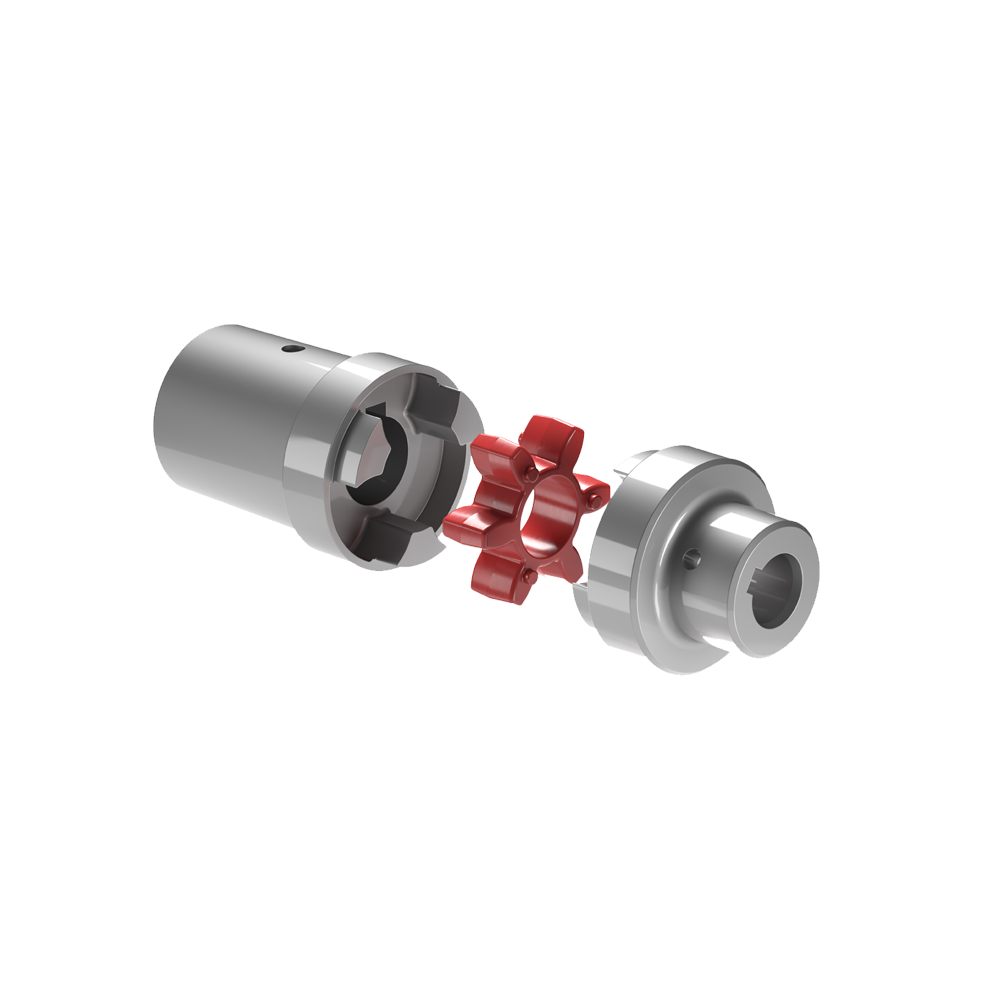

SGDR - EGR

SGDR - EGREngine flexible half couplings

Steel half couplings specifically designed to suit high torque applications with parallel or splined shafts, easy to install and save time on maintenance and repairs

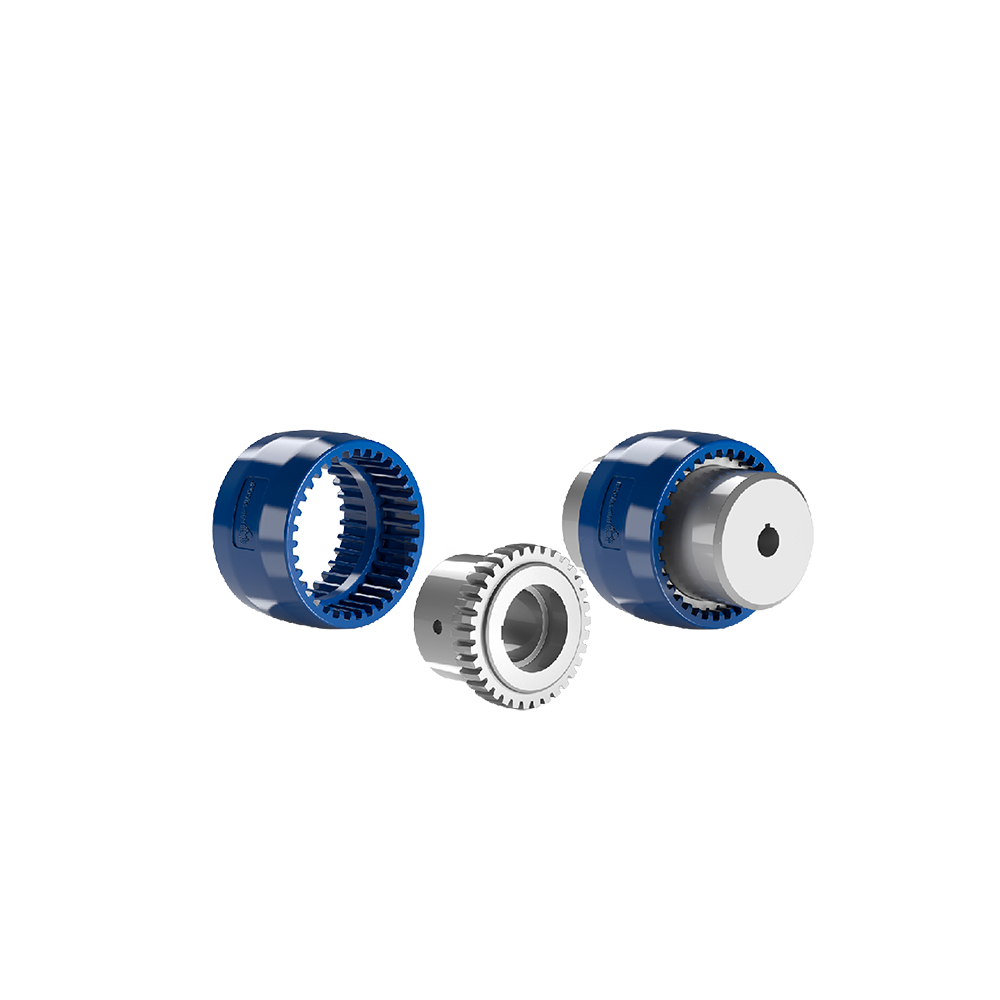

AKG

AKGComplete Coupling

Available in aluminum, cast iron, and steel. NBR or Polyurethane spider.

They can be used for mounting electric motors and gear pumps, piston pumps, and screw pumps.

SGES + EGE (E-PTO SYSTEMS)

SGES + EGE (E-PTO SYSTEMS)e-PTO Couplings

Available in steel

Designed to power the onboard hydraulic systems of heavy vehicles, it uses the electric energy of a Banke e-PTO instead of traditional diesel.